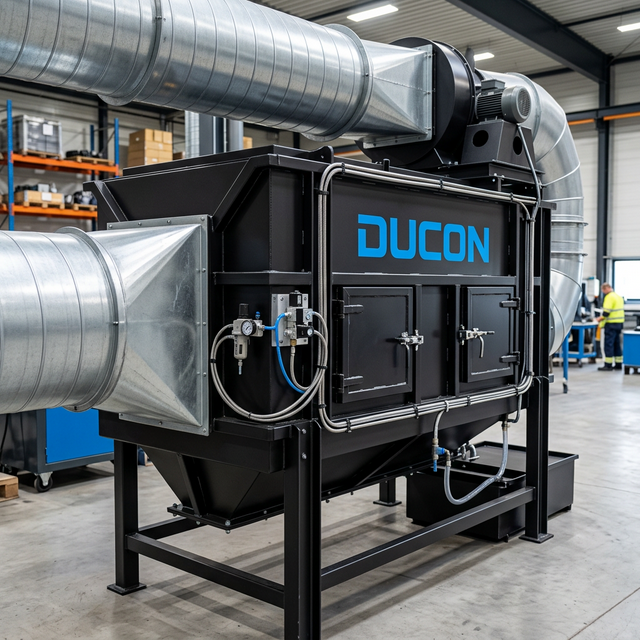

DUCON Dilute Phase Pneumatic Conveying

DUCON Dilute phase pneumatic conveying is a method of moving non abrasive, non-fragile materials that have a lower bulk density. The system incorporates a high gas volume, low pressure process, entraining the materials and generally conveys one of two ways: pressure or vacuum. In pressure conveying a high volume of low-pressure air transfers material at a high velocity. In vacuum conveying a high volume of negative-pressure air transfers material at a high speed. Common materials suitable for dilute phase pneumatic conveying are flours, resins & compounds, specialty chemicals, and more.

A COST-EFFECTIVE WAY TO CONVEY NON-FRIABLE,

NON-ABRASIVE MATERIALS

DILUTE PHASE

PNEUMATIC CONVEYING

OUR SOLUTIONS